[Aluminum Road Network] What is a seamless welding process?

The conventional aluminum alloy doors and windows of the broken bridge are assembled from aluminum. The aluminum joints are not specially treated. The conventional aluminum-clad wooden doors and windows are made of wood and aluminum, and the outer aluminum joints are not treated and have gaps. Seamless welding doors and windows introduced seamless welding machine, so that the door and window revolution into the 4.0 era, the outer aluminum frame seamless welding, after grinding and then do the surface coating, making the aluminum frame joints seamlessly, improve the sealing performance and decorative performance of doors and windows.

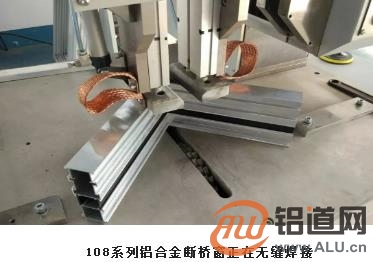

Seamless welding machine: seamless aluminum welding machine, 45 ° angle seam welding, medium T-type welding, cross welding special doors and windows equipment. This machine is controlled by Panasonic system in Japan, with cylinder pressing, infrared correction, automatic center line, input profile weld length, automatic welding, automatic welding on the back of the profile input welding, and clearing the front welding knob, eliminating the need for a processing process ( Cylinder compression - lower gun - welding - receiving gun, flip profile - back spot welding - remove front welding knob). The profile program only needs to be entered once, automatically stored, and used at will. Truly tailor-made aluminum alloy, aluminum package wood seamless welding full set of programs.

Traditional manufacturing process

The traditional manufacturing of doors and windows is actually a process of assembly. No matter what big name, big factory or workshop he is, in fact, its production process is basically the same. The six-meter-long profile that has been spray-molded is cut to the required length, and then the profile is subjected to milling, drilling, and spelling. This process flow will inevitably cause surface wear and secondary damage to the profile. The accuracy of processing cannot be guaranteed fundamentally.

Metal splicing, gaps can not be avoided;

Followed by the leakage of air leakage, not sound insulation, etc. can not be avoided;

Traditional craftsmanship will inevitably spliced ​​into a 90-degree angle, whereby it will form a very sharp corner;

Usually many families, especially families with young children. How many cases have been hurt by this sharp corner;

However, our conventional solution is to put a bumper guard on it like a plaster.

Seiko seamless welding process features:

1. Beautiful appearance, better insulation and sealing performance

Seamless welding is an upgraded version, using seamless welding technology, aluminum outside the formation, the level of simplicity; no bump, more beautiful and more decorative performance; can make the doors and windows better play the effect of sound insulation, heat insulation.

2. The frame is more sturdy, not easily deformed, extending the service life of doors and windows

We know that the thermal expansion and contraction of aluminum due to seasonal changes may cause water leakage from the doors and windows due to cracks, which will corrode internal profiles and endanger the life of doors and windows. If the seamless welding process is used for doors and windows, the above problems are well avoided. The window frame is more sturdy and the spraying of the door and window joints is more uniform.

The upgrading of door and window technology in China is relatively slow. Building doors and windows have become large energy consumers in China's buildings, accounting for at least 25% of the total. In order to reduce energy consumption, the country has carried out four energy saving reforms: the first energy saving reform will save energy in buildings. To 35%, the second energy-saving reform will increase the energy efficiency of buildings from 35% to 50%. The third energy-saving reform will increase the energy efficiency of buildings from 50% to 65%. The fourth step is to save energy in the third step. On top of that, another 30% is saved, which is the so-called 75% building energy efficiency.

As one of the surface enclosures of buildings, doors and windows directly affect the energy-saving performance of buildings, and improving the insulation performance of doors and windows is the main way to ensure the energy consumption of buildings. Nowadays, energy-saving doors and windows of buildings are increasingly drawing attention.

The real energy-saving system doors and windows are not a single insulation profile or a Low-E insulating glass energy-saving material. It is a perfect combination of systems, and the integrated results of all aspects are indispensable. It is important to measure the energy efficiency of building doors and windows. Consider three elements, namely the convection of heat, the conduction of heat, and the radiation of heat:

1. The loss of heat is through the use of hot and cold air circulation through the gaps between doors and windows. Heat is exchanged through the convection of gases, resulting in heat loss.

2. Heat conduction is the transfer of heat by the molecular motion of the material used in the door and window itself, which is transferred to the other surface through the material itself, resulting in heat loss;

3. Radiation is transmitted directly in the form of radiation, resulting in energy loss.

Broken bridge seamless welding is an innovation in the door and window industry. It effectively improves the heat loss of doors and windows and is an important milestone in the development of energy-saving systems.

We can produce the lower-temperature Steel Pipe according to the ASTM A333 and ASME SA333 standards, and the and the production diameter from 8" to 48" in OD and wall thickness from 9.53 mm up to 140mm. We have been sold the GR.6 steel pipe about 20000 tons to date and the property of -45℃ impact value is about 100J, better than the standard`s requirements.

Yangzhou Chengde has the full capability to do every test in-house, from mechanical testing, chemical analysis, PMI, UT/Hydrotest etc. Chengde`s lab is qualified to ISO 17025 and CNAS standard, being proven the repeatability of accurate testings.

Each alloy pipe is subject to PMI before dispatch. The INNOV-X system performs non-destructive chemical analysis via simultaneous detection and quantification of fluorescent x-rays of multiple elements in test sample.

A333 Pipe,Astm A333 Pipe,Astm A333 Tube,Gr 6 Pipe

YANGZHOU CHENGDE STEEL PIPE CO.,LTD , https://www.chengdepipe.com