The butt welder is a spring upset forge welder. This model is used as an example to illustrate the operation of the welder. Check and preparation before use, check whether the welder is in normal condition, whether the connection of each part is correct and reliable, whether the power supply voltage meets the requirements, whether the welding fixture clamping force and the clamp jaw distance meet the requirements, pedals, shift switches and Whether the mechanism such as the fixed fixture is flexible and reliable.

Adjustment of the welder. According to the material and section size of the weldment, the following adjustments are made: 1 Estimate the magnitude of the welding current, and then select the number of steps of the secondary voltage regulating switch. 2 Estimate the clamping force of the clamp. The clamping force should be such that the clamp does not slip when welding the workpiece. Adjust the clamping force by adjusting the tightness of the lock nut. 3 Appropriately reserve the forging amount. The larger the cross section of the weldment, the larger the forging amount is reserved. The smaller the cross section is, the smaller the forging amount is reserved, and the amount of forging is reserved. The welded joint is welded and welded firmly. The diameter of the annular weld is about 2~3mm larger than the diameter of the base metal. The adjustment of the reserved forging amount can be carried out by the upsetting adjusting nut in the welding motor clamp. The power-off moment of the welding process is matched with the clamp. The length of the workpiece before welding is guaranteed. 4 Estimate the size of the upset forging, the larger the section of the workpiece is, the larger the forging pressure is. The smaller the section is, the smaller the forging pressure is. The tightening of the large nut on one side of the fixture can be achieved by twisting the welder. Adjustment. Synchronously adjusted with the welding current, the amount of reserved forging and the moment of forging and forging, so that the welding head can obtain a firm welding head without forming an excessive annular flash, which is limited by the material length. Adjustments in this area are particularly important because you cannot reserve too many workpieces and workpieces that have been welded to have the required dimensions (such as ring-shaped workpieces). 5 Adjust the jaw opening, which can be adjusted by the nut below the pedal link.

Material: SS304, SS316

Weave type: Plain weave, Twilled weave, Dutch weave

Features: Corrosion-resisting, Wear-resisting

Uses:Mainly used for filtering and sieving, extensively used in petroleum, chemical industry, enviroment protection,

mine, airspace, paper-making, electronic, metallurgy etc.

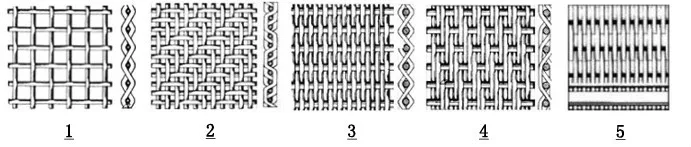

Weave type explanation

1. Plain Weave: also called tabby weave, linen weav or taffeta weave, is the most basic type of weaves.

In plain weave, the warp and weft are aligned so they form a simple criss-cross pattern. Each weft thread

crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under

the warp threads that its neighbor went over, and vice versa.

2. Twill Weave: In a twill weave, each weft or filling yarn floats across the warp yarns in a progression of interlaces

to the right or left, forming a distinct diagonal line. This diagonal line is also known as a wale. A float is the portion of

a yarn that crosses over two or more yarns from the opposite direction.

3. Plain Dutch Weave: similar with plain weave, just the weft and warp wire have different wire diameter and different mesh size.

4. Twill Dutch Weave: similar with twill weave, just the weft and warp wire have different wire diameter and different mesh size.

5. Reversed Dutch Weave: difference from standard Dutch weave lies in the thicker warp wires and less weft wires

Stainless Steel Series,Stainless Steel Wire Mesh,Stainless Steel Crimped Wire Mesh,Stainless Steel Window Screen

Anping Shengjia Hardware Mesh Co.,LTD , https://www.oilshaleshakerscreen.com