When wearing a hard hat, it's essential to follow proper procedures to ensure maximum protection. Before putting on the safety helmet, adjust the rear adjustment system according to your head size and secure the chin strap properly. The cushioning pad inside is pre-adjusted at the factory, but it's important to ensure there is a vertical gap of about 25–50 mm between the top of your head and the inner part of the helmet. This space allows for effective shock absorption during impact and also improves ventilation. At minimum, this distance should not be less than 32 mm.

The primary purpose of a helmet is to protect the worker’s head from falling objects. When an object strikes the helmet, the cap and the liner work together to spread the impact force over the entire surface of the skull. The helmet’s structure is designed to absorb most of the impact through elastic and plastic deformation in various parts, reducing the force that reaches the head to 4900 N or less. This helps prevent serious injury.

To ensure the helmet functions as intended, it must be selected carefully and used correctly. Always choose a qualified helmet that meets safety standards and follow the manufacturer's instructions for proper use.

1. **Shock Absorption**: There should be a gap of 25–50 mm between the outer shell and the inner liner. When an object hits the helmet, the shell deforms slightly without directly impacting the head.

2. **Stress Distribution**: The helmet's shape—usually oval or hemispherical—helps distribute the impact force across the entire surface. This reduces the pressure on any single point and prevents localized damage.

3. **Biomechanical Protection**: According to national standards, helmets are tested to absorb up to 4900 N of force. This limit is based on human biomechanics; exceeding it can cause serious spinal injuries, including paralysis or even death.

Before wearing the helmet, always inspect it for damage. Check if all parts are intact, the adjustment system is secure, and the straps are tight. Adjust the inner band so it fits snugly but comfortably. For high-altitude workers, make sure the chin strap and neck support are firmly fastened to prevent the helmet from slipping off.

If the helmet has been struck and shows visible cracks or deformation, stop using it immediately and replace it. Most helmets have a lifespan of around three years. Even if no obvious damage is present, regular inspections are necessary to check for cracks, dents, or wear. Any helmet that has suffered a severe impact, even if it appears undamaged, should be discarded. Safety should never be compromised.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Yokelink has been supplying fasteners for the wind energy industry for over 10 years. These fasteners are utilised in producing a gearbox, a valuable wind mill turbine component located within the nacelle. we also offer standard wind power energy fasteners in line with ISO or DIN, including vibration-resistant security products. Wind tower bolt plays a important role as joining components in fastening different parts of wind turbine tower, Yokelink is a professional manufacturer which supplies high grades fasteners 8.8-12.9 for wind tower projects.

Product Ranges:

We currently service all aspects of the wind turbine market, Our extensive range allows wind

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

â—Foundation

â—Tower Construction

â—Blade to Hub

â—Nacelles

â—Off-shore Transition Pieces

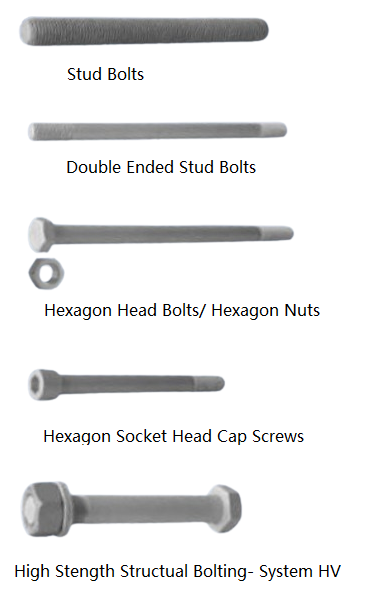

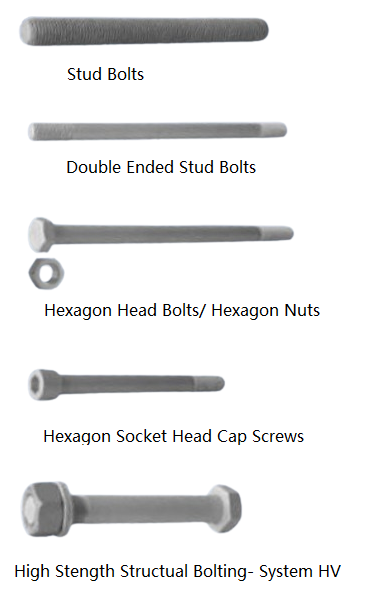

Hex cap screws DIN 931, DIN 933 and ISO 4017

Hex Bolts and Nuts, size M10-M64

Stud Bolts size M12-M64

Threaded Rods size M10-M64

Tower Flange Bolts size M10-M64

WHAT ARE WINDMILL POWER FASTENERS?

WHAT ARE WINDMILL POWER FASTENERS?

Fasteners used in wind power tower and blade connection and transmission, including hex bolts, stud bolts, tower flange bolts, foundation bolts, threaded rods, high strength double head screw, hardened and structural bolts, nuts, washers and threaded rods, and hex cap screws etc.

WHAT'S THE CHARACTERISTICS OF WIND POWER FASTENERS

High strength, high grade and precision, can work in hard conditions like extremely hot and cold environment and corrosion resisted .In wind turbine generator system, because of the randomness of power source, hardness of operating circumstances, special producing and installing, as well as high costs of maintaining, the requirements for wind turbine bolts would be extremely high. We have to take effective actions to ensure the reliability of the bolts connection, from the bolts structure design, manufacture process to production and assembling.

WHAT BOLTS ARE USED IN A WIND TURBINE?

Wind turbine bolts, there are wind turbine blade bolts, wind turbine anchor bolts, wind turbine foundation bolts, high strength and high tension hexagon head bolts, nuts and washers are mainly used for wind turbine.

HOW MANY BOLTS ARE IN A WIND TURBINE?

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

When you need Wind Power Fasteners, refer to above our catalog. We offer them in a full selection of sizes, provide the diameter or part number to get a quote of wind power fasteners, leave your message, or send us an email. You can also call us to get answers to your questions and place your order.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Wind mill ,Wind Power fasteners, Wind mill Turbine, Stud Bolt, windmill energy, house wind turbine, Wind Turbine Blades

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com